Function:

The test equipment simulates corrosion tests in artificial environments and is used to test the quality of metal materials with or without anti-corrosion protection; it is suitable for rapid analysis of organic and inorganic coatings, such as discontinuities, holes and damage, and other phenomena. In addition, for the purpose of quality control, it can be compared between samples coated with the same coating. Salt spray tests are particularly suitable for detecting discontinuities such as pinholes and other defects in certain metals, organic anodized and conversion coatings.

The equipment is used to conduct various accelerated tests such as high temperature tests, wet heat tests, and salt spray systems for test pieces, materials and their components.

Major Specifications:

| Product Name | Walk-in Multi-Environment Corrosion Chamber |

| Product Model | CZ -20000D |

| Nominal content | 19.5m³ |

| Inner box size(mm) | 3200×1900×3200WXHXD |

| Outer box size(mm) | About 3450×2300×4710WXHXD

Note: Does not include the size of the salt water tank, pure water tank, steam generator, and mist filter |

| Brine tank size(mm) | Outer box size: width 700×height 1500×depth 1200, inner box size: width 500×height 1000Xdepth 1000, volume about 500L

Note: The equipment is equipped with three brine tanks of the same specifications. The water supply pipe is connected to the water inlet of the brine water supply pump, and the water supply to different water tanks is switched through a ball valve. The water tank is equipped with a liquid level sensor, a water inlet float valve, a brine stirring motor, a salinity sensor, and a PH meter |

| Pure water tank | The pure water tank is made of 1.2mm stainless steel and is equipped with a liquid level sensor and a float valve, with a low liquid level alarm function; used for equipment spraying and humidification boiler water supply |

| Steam generator size(mm) | About 450×1000×750 WXH×D |

| Mist filter size(mm) | About 500×1000×790 WXHXD |

| Equipment Net Weight | About 5000kg |

| Test environment conditions | The ambient temperature is +25℃, the relative humidity is ≤85%RH, the atmospheric pressure is 86~106Kpa, and there is no sample in the test chamber. |

| Device Functions | Salt spray test mode, wet heat mode (including dry, wet heat), spray mode. The three test modes can be switched at will, and can be programmed for combined testing or separate functional testing |

| Control accuracy | Temperature resolution: 0.01℃

Humidity resolution: 0.1%R.H Temperature deviation: ≤±2.0℃ Humidity deviation: ≤+2-3%R.H when ≥75%RH; Humidity deviation: ≤±5%R.H when <75%RH; Temperature uniformity: ≤2℃ Humidity uniformity: ≤+2-3%R.H when ≥75%RH; Humidity deviation: ≤±5%R.H when <75%RH Temperature fluctuation: ±0.5℃ Humidity fluctuation: ±2%R.H Note: Temperature uniformity and deviation are values measured at an ambient temperature of +25℃, relative humidity ≤85%R.H, and without a sample. |

| Noise | Less than 75db (measured 1m from the front of the cabinet and 1.2m from the ground) |

| Salt spray test functions and parameters | Temperature range | Ambient temperature ~ 55℃ adjustable |

| Salt spray deposition | 1~3ml/(h ·80cm²) adjustable (take the average value after collecting for more than 16 hours)

Note: Since the top of the equipment is made into a flat top structure, the spray collection amount will be affected by the dripping of condensed water on the top, so the uniformity of spray collection is not considered |

|

| Spray method | Can perform continuous/interval program setting, with quantitative control function; | |

| Spray system | The filter installed in the salt water tank can be cleaned and reused repeatedly; each nozzle can be fine-tuned in angle, and can be disassembled and cleaned; | |

| Salt water concentration | 5%±1% or specified value (the brine tank is equipped with a brine concentration sensor to monitor the brine concentration online) | |

| pH value of salt water | Neutral 6.5~7.2, acidic 3.0~3.2 (the brine tank is equipped with an electronic pH meter to monitor the pH value of the brine online) | |

| Saturator temperature range | Ambient temperature ~70℃ adjustable; | |

| Test conditions | Neutral Salt Spray (NSS)/Acetic Acid Spray (AASS)/Copper Accelerated Acetic Acid Spray (CASS)

Note: The equipment can meet the above three test conditions. In order not to affect the test results, it is not recommended to use the same equipment for neutral and acid tests. Because it is very difficult to clean the test chamber used for AASS or CASS tests for NSS tests. |

|

| Spray pressure | 70~170Kpa | |

| Wet heat/dry mode | Temperature range | 20~70℃ adjustable |

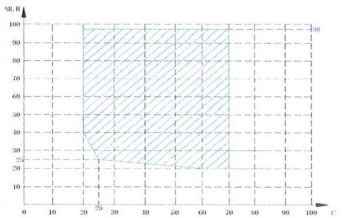

| Humidity range | 20%R.H~98%R.H(as shown in the figure)

|

|

| Heating rate | 20→70℃≥3℃/min (under average no-load condition throughout the process) | |

| Cooling rate | 70℃→20℃≥1.2℃/min (under average no-load condition throughout the process) | |

| External heat source | 12KW (Considering cooling load) | |

| Spray test mode | Spray water source | Pure water tank |

| Water spraying cycle | The water spraying cycle can be adjusted. The typical cycle is to spray water for 18 minutes every 102 minutes, or spray water for 12 minutes every 48 minutes, etc. | |

| Spraying area | 3m×3m, in the middle of the box | |

| Meet the test method | D0160E/F/G Salt spray test requirements

GJB150.11A-2009 Military equipment laboratory environmental test method salt spray test; GB/T2423.18-2021/IEC60068-2-52:2017 “Basic regulations for testing of electrical and electronic products” Kb: Salt spray alternation (sodium chloride solution) GB/T2423.17-2008/IEC 60068-2-11-1981 Environmental testing for electrical and electronic products Part 2: Test method test Ka salt spray GB/T10125-2021/IS09227:2017 Artificial atmosphere corrosion test salt spray test GB/T2423.3-2016/IEC60068-2-78:2012 Environmental testing Part 2: Test method test Cab: Steady damp heat Test GB/T 2423.4-2008/IEC60068-2-30:2005 Environmental testing for electrical and electronic products Part 2: Test methods Test D b: Cyclic damp heat (12h+12h cycle) GB/T 31467.3-2015 Lithium-ion power battery packs and systems for electric vehicles Part 3: Safety requirements and test methods: Salt spray test; |

|

| Equipment meets the test method | GB/T5170.5-2008 Wet heat test equipment test method | |

| Noise | Less than 75db (measured 1m from the front of the cabinet and 1.2m from the ground) | |

| power supply | AC(380±10)V (50±0.5)Hz three-phase four-wire + protective grounding | |

Product Details:

Controller | Details

Frequently asked questions

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

Reviews

Clear filtersThere are no reviews yet.