Function:

1. The corrosion of protected and unprotected metal materials is affected by many environmental factors, which mainly depend on the type of metal material and the type of environment. It is impossible to design a laboratory accelerated corrosion test room that includes all environmental factors that affect corrosion resistance. Therefore, the laboratory test is designed to simulate the factors that play a major role in the corrosion of metal materials. This equipment is designed to simulate and increase the impact of the environment on metal materials exposed to outdoor atmospheres with salt pollution and accelerated corrosion. The equipment includes test methods for cyclic exposure of specimens to salt spray, dry, and hot and humid environments. This equipment test is a comparative test, and the test results cannot predict the long-term results of the corrosion resistance of the same metal material used under these environmental conditions. However, this method can still provide valuable information on the relevant performance of materials exposed to salt pollution environments similar to the test conditions. Compared with traditional accelerated corrosion tests such as neutral salt spray test (NSS), acetic acid salt spray test (AASS), and copper accelerated acetic acid salt spray test (CASS), the biggest advantage of this equipment test is that it can better reproduce the corrosion occurring in outdoor salt pollution environments.

2. The equipment is a temperature and humidity alternating salt spray composite tester with temperature and humidity adjustment function, which is used to detect various performance indicators and quality management of accessories under alternating composite conditions such as high temperature, humidity, dryness, and salt spray.

3. The equipment has an emergency braking function, and a brake switch is installed on the equipment. When an abnormal situation occurs, the equipment can be powered off by controlling the switch.

4. The equipment is equipped with corresponding system software, which can run stably on the provided operating system. The software interface is in Chinese or English; the software includes temperature change test, humidity, precision calibration part, and equipment self-test module part.

5. The system software can record, automatically save, and optimize data in real time. It can draw temperature-time, humidity-time and other curves through software settings.

6. The system software is set with a security protection parameter interface, and after the setting is completed, it will be given priority during the test process to ensure the safety of the test.

7. The system software can achieve the function of test data security protection. The software has an administrator function and can limit the operating permissions of general operators.

8. The system software has the function of post-data processing, and can support the import of multiple data files, support data screening, and support any X-axis and Y-axis selection.

Product Details:

Major Specifications:

| Product name | Walk-in composite salt spray test chamber |

| Product model | CZ-12500D |

| Specimen restrictions | This test equipment prohibits:

Testing or storing samples of flammable, explosive, and volatile substances Testing or storing samples of corrosive substances Testing or storing samples of biological substances Testing or storing samples of strong electromagnetic emission sources Testing and storing samples of radioactive substances Testing and storing samples of highly toxic substances Possible generation during testing or storage Testing and storing samples of highly toxic substances |

| Nominal content volume | 12.5m3 volume without top sloping roof |

| Inner box size (mm) | 2500×2500×2000 W×H×D

Note: The top angle is 115°, the top height is 880mm |

| Outer box size (mm) | About 4400×3800×2500W×H×D |

| Brine tank size (mm) | About Φ1000mm×H1300mm |

| Net weight of equipment | About 2900kg |

| Test environment conditions | Ambient temperature is +25℃, relative humidity ≤85%RH, atmospheric pressure is 86~106Kpa, and there is no sample in the test box |

| Test room temperature range | 20℃~+70℃ |

| Saturated barrel temperature range | RT~65℃ |

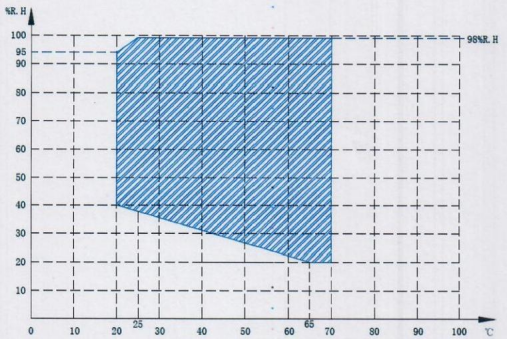

| Humidity range | 20%R.H.~98%R.H as shown in the figure

|

| Test conditions | a. Common alternating salt spray test conditions: at 35℃ ambient temperature, 47℃ saturated barrel temperature, 5% brine The concentration spray test time can be set arbitrarily from 1min to 999h. The temperature of the wet heat test is 50℃±2℃, the relative humidity is 93%RH±2%RH, and the test time can be set arbitrarily from 1min to 999h. The cycle can be set arbitrarily from 1 to 999 times. Then, it can be set arbitrarily from 1min to 999h in a standard environment with a temperature of 23℃±2℃ and a relative humidity of 50%RH±5%RH.

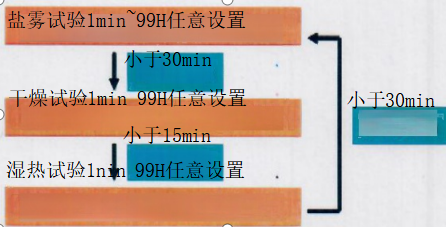

b. Dry-wet composite salt spray test conditions: 35℃ ambient temperature, 47℃ saturated barrel temperature, 5% salt water concentration spray test time 1min~999h can be set arbitrarily; then switch to 60℃ ambient temperature within 30min, relative humidity below 30%RH for drying test, test time 1min~999h can be set arbitrarily; then switch to 50℃±2℃ temperature within 15min, relative humidity 95%RH±3%RH humid and hot environment, test time 1min~999h can be set arbitrarily; cycle 1~999 times can be set arbitrarily. Then return to the first step of salt spray test. The drying, damp heat, and salt spray alternating process is as follows:

C. NSS salt spray test, AASS acetic acid salt spray test, CASS copper accelerated acetic acid test, damp heat test, drying test, standard macroclimate environment test test conditions or other combined test conditions can be carried out separately |

| Control accuracy | Temperature resolution: 0.01℃

Humidity resolution: 0.1%R.H Temperature deviation: ±2℃ Humidity deviation: ≤+2-3%R.H when ≥75%RH; Humidity deviation: ≤±5%R.H when <75%RH; Temperature uniformity: ≤2℃ Humidity uniformity: ≤+2-3%R.H when ≥75%RH; Humidity deviation: ≤±5%R.H when <75%RH; Temperature fluctuation: ±0.5℃ Humidity fluctuation: ±2%R.H Note: Temperature uniformity and deviation are under ambient temperature of +25℃, relative humidity ≤85%R.H, and no test The value measured under the sampling conditions. |

| Salt spray deposition | 1~3ml/h/80cm² (collect for at least 16 hours and take the average value) |

| Spray pressure | 70~170Kpa (recommended spray pressure 100Kpa±1Kpa/lkgf/cm²±0.01 kgf/cm²) |

| PH value | 6.5~7.2 |

| Meet the test method | GB/T 20854-2007/IS014993-2001 Corrosion of metals and alloys Accelerated test under cyclic exposure to salt spray, “dry” and “wet” conditions;

GB/T24195-2009/ISO 16151:2005 Cyclic accelerated corrosion test under acidic salt spray, dry and wet conditions; GB/T 20853-2007/ISO 16701:2003 Corrosion of metals and alloys Corrosion in artificial atmosphere Accelerated corrosion test under controlled conditions of intermittent spraying of salt solution and humid cycle; GB/T 2423.17 “Basic environmental test procedures for electrical and electronic products Test Ka: Salt spray test method” GB/T 2423.18-2012 “Basic test procedures for electrical and electronic products” Kb: Salt spray alternation (sodium chloride solution)” GB/T 10125-2012/IS09227-2006 “Artificial atmosphere corrosion test salt spray test” GB/T 31467.3-2015 Lithium-ion power battery packs and systems for electric vehicles Part 3: Safety requirements and test methods: Salt spray test; ASTM B117-2011 Salt spray test ASTM B368 GB/T 2423.2-2008 Test B: High temperature test method; GB/T 2423.3-2006 Test Ca: Steady heat test; GB/T 2423.4-2008 Test Db: Alternating damp heat test; GB/T 10587-2006 Technical conditions for salt spray test chambers; GB/T 10586-2006 Technical conditions for damp heat test chambers; GB/T 5170.8-2008 Inspection methods for environmental test equipment for electrical and electronic products Salt spray test equipment GJB150.11A-2009 Laboratory environmental test methods for military equipment Salt spray test D0160 E/F/G Environmental test for airborne communication equipment Salt spray test |

| Noise | Less than 75db(A) (measured 1m from the cabinet and 1.2m from the ground) |

Frequently asked questions

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

Reviews

Clear filtersThere are no reviews yet.