Multi-coupled Climate Comprehensive Environment Simulation Laboratory

Product Description:

The equipment is primarily used to artificially simulate climatic conditions such as rainfall, sunlight, humidity, low temperatures, wind, snow, and ice accumulation to test the product’s environmental resistance and reliability.

Product Details:

Major Specifications:

| 1.Volume, weight, dimensions and specifications | ||

| 1.1. Product Name | Multi-coupled climate comprehensive environment simulation laboratory | |

| 1.2. Product Model | CZ-ZH-48000F | |

| 1.3. Test chamber volume | 48m3 | |

| 1.4. Test chamber inner dimensions (mm) | 4000×3000×4000 W×H×D | |

| 1.5. External space (mm) | Approximately 4300 x 3400 x 5300 W x H x D

Note: The actual dimensions are subject to change. |

|

| 1.6.Refrigeration unit cabinet size (mm) | 950×1500×2000 W×H×D

Note: The refrigeration cabinet is installed outdoors, and the equipment is installed near the window on the first floor. The user needs to drill a hole in the wall at the installation site, with a diameter of 250mm. The refrigeration cabinet needs to be shed for waterproof protection. The ground where the cabinet is installed needs to be hardened. The shed for the cabinet installation is part of the infrastructure and is handled by the user. |

|

| 1.7.Chiller size (mm) | 2070*1950*950(W*H*D)

Note: The chiller is installed outdoors near the refrigeration unit cabinet. |

|

| 1.8. Equipment weight | About 8 tons | |

| 1.9. Working noise | ≤75db measured in front of the machine, 1 meter away from the machine and 1.2 meters above the ground | |

| 1.10.Test product specifications | Product material | dummy |

| size | The height of the dummy is 1500-1900mm, and the length and width are less than 1 meter. | |

| weight | 100Kg | |

| fever | 120W | |

| Number of pieces | 1 product tested | |

| 2. Device power, current, and power supply | ||

| 2.1.Total equipment power | Total installed power 160KW, maximum operating power 95KW | |

| 2.2.Maximum operating current | 140A | |

| 1.1.Power supply conditions and power supply

|

AC 380V three-phase four-wire system with protective grounding; voltage fluctuation range ±10%V;

Frequency fluctuation range 50±0.5Hz; TN-S or TT power supply. Protective ground wire resistance less than 4Ω. The user is required to configure an air or power switch of appropriate capacity for the device at the installation site. This switch must independently control the device. When placing powered samples in the chamber, use an external power supply for the samples; do not use the device’s power supply directly. |

|

| 2. Main technical parameters of the equipment | ||

| 2.1.Test Mode | Temperature and humidity test mode (including high temperature, low temperature, humidity control), sunlight simulation mode, wind speed test mode, rainfall test mode, snowfall test mode, and ice test mode can be freely set | |

| 2.2.Temperature and humidity test conditions | Temperature range | -60~80℃ |

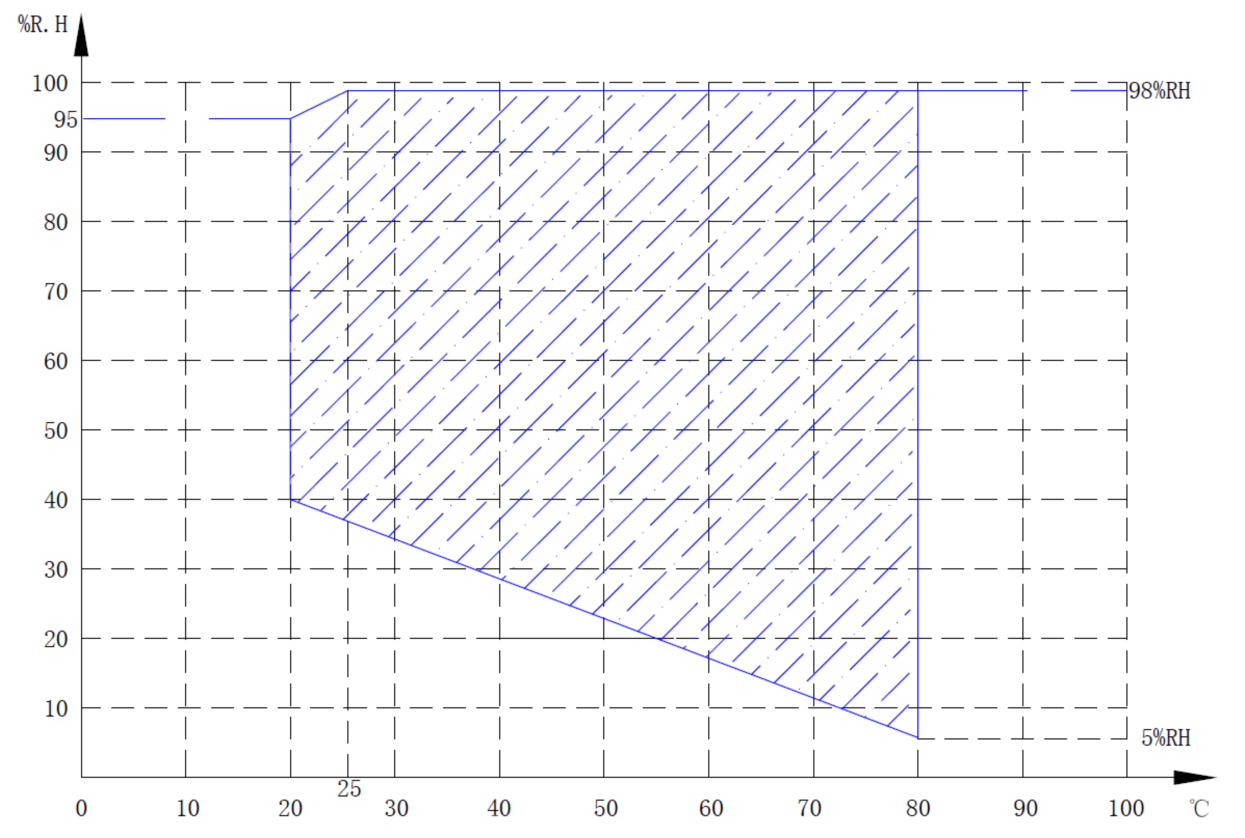

| 3.1 | Humidity range |  5%R.H~98%R .H 5%R.H~98%R .H |

3.2 |

Display resolution | Temperature resolution: 0.01°C

Humidity resolution: 0.1%RH |

| 3.3 | Temperature control stability | ±0.6℃ |

| 3.4 | Temperature measurement accuracy | ±0.1℃ |

| 3.5 | Temperature uniformity | ≤2℃ |

| 3.6 | Humidity deviation | ≤±3% R.H. (≥75% R.H.) ≤±5% R.H. (<75% R.H.) |

| 3.7 | Humidity measurement accuracy | fs±3%RH |

| 3.8 | Heating and cooling rate | Under no-load conditions, the time from room temperature (20℃) to the lowest temperature (-60℃) does not exceed 2 hours, and the time from room temperature (20℃) to the highest temperature (80℃) does not exceed 2 hours. |

| 2.3.Wind speed test conditions | Blowing form | Movable fan array, horizontal airflow, adjustable height

Note: The fan array can be arranged horizontally or vertically |

Test Standards:

1. GB/T 2423.1-2008/IEC6008-2-1-2007 Environmental testing for electric and electronic products – Part 2: Test methods – Test A: Low temperature

2. GB/T 2423.2-2008 Environmental testing for electric and electronic products – Part 2: Test methods – Test B: High temperature

3. GJB150.3A-2009 High temperature test method

4. GJB150.4A-2009 Low temperature test method

5. GB/T 2423.22-2008 Environmental testing for electric and electronic products – Part 2: Test methods – Test Nb: Temperature change at a specified rate of temperature change

6. GB/T 39605-2020 Wetness resistance test method for clothing – Sweating manikin method

7. GB/T 38426-2019 Determination of thermal resistance and operating temperature of sleeping bags

8. Prototype or data support source for global standards: ASTM F1291, ASTM F1720, ASTM F2370, ASTM F2371, ISO 23537, ISO/DIS 15831

9. GB/T10586-2006 Technical Specifications for Humidity and Heat Test Chambers

10. GB/T5170.9-2008 Test Methods for Environmental Test Equipment for Electrical and Electronic Products – Solar Radiation Test Equipment

Frequently asked questions

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

A seemingly elegant design can quickly begin to bloat with unexpected content or break under the weight of actual activity. Fake data can ensure a nice looking layout but it doesn’t reflect what a living, breathing application must endure. Real data does.

Websites in professional use templating systems. Commercial publishing platforms and content management systems ensure that you can show different text, different data using the same template. When it’s about controlling hundreds of articles, product pages for web shops.

Reviews

Clear filtersThere are no reviews yet.